About Us

About Us / Products / Contact Us / Technical-Data / Brochure

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

About Us / Products / Contact Us / Technical-Data / Brochure

loading

| Availability: | |

|---|---|

|

| |

Turbidity Barrier

Turbidity Barrier is an economical , universal barrier for intercepting oil spills and other floats on waters. It is made of high strength vinly fabric with light weight foam inside. The Floating turbidity barrier is widely used on rivers, harbors , lakes, offshore oil platforms and other waters, due to its fast install and easy operation.

Turbidity barriers are used to keep the top edge of the barrier above water level. Standard depth of 5 feet with custom depths available. Staked barriers can be used in shallow water.

5’X50’ Turbidity Barrier

Type1 Specification

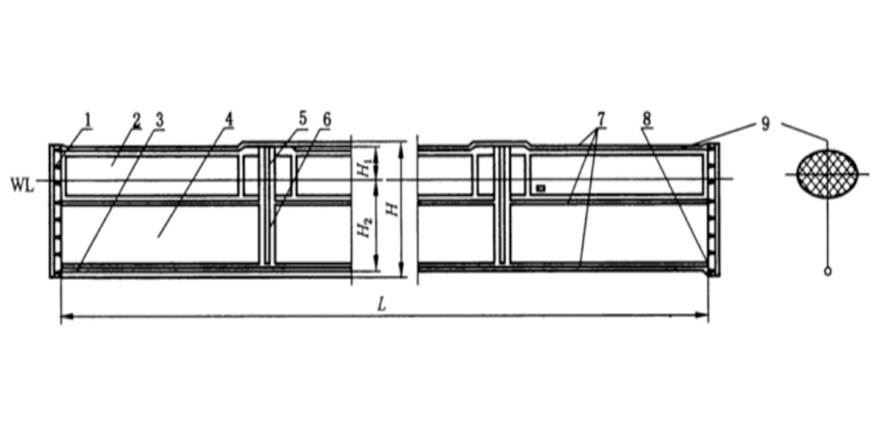

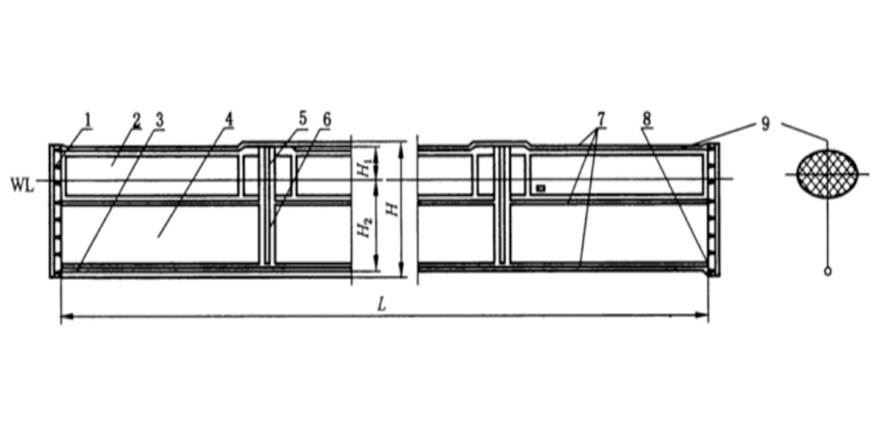

Floating Turbidity Barrier Basic structure diagram

1. End connector 2. Floatation 3. Ballast 4. Shirt 5. Flexibility gap section 6. Stiffener ( according to design) 7. Tension member 8. Anchor Point 9. Fin H1 : Freeboard (height above water) H2: Draft ( height below water) H : Width ( H1 + H2) L : Length WL : Water level

18.5oz laminated vinly/pvc fabric meets the following specification

| Construction | 1300 Denier | 9x9/sq.inch |

| Weight | 18.5oz/sq.yd | ASTM D-2374 |

| Adhesion | 15 lb/inch | ASTM D-751-95 |

| Grab Tensile | 390 x 370lbs | ASTM D- 5034 |

| Tear Strenght | 96x86 lbs | ASTM D- 2261 |

• Heat sealed seams

• 5/8” polypropylene twisted rope edge reinforcement

• 6”x6”x48” EPS foam blocks

• #4 brass grommets in edge for laced connection

• Smart “Z” connector as option

• ¼” galvanized steel ballast chain

Features

• Economical Silt Control

• Easy to Connect and Install

• Effective Control in Shallow or Slow Moving Areas

• Strong Impermeable PVC Barrier

• Brightly Colored for Easy Spotting

• Lengths Up to 100' to Fit Various Size Projects

• 4 in. Flotations to Fit Smaller Areas

Applications

Construction Sites - Silt and dirt sediments from construction move through the air and eventually land in the surrounding water areas. Turbidity barrier sit in the water and stop silt, dirt, or debris from continuing past the barrier, eventually causing the sediment to settle to the bottom.

Environmental Remediation - Turbidity barriers can also be used in environmental remediation to prevent toxic chemicals and heavy metals from leaving the worksite.

Marine Life Protection - Turbidity barriers work to control the release of organics in the water column, which at concentrated levels can be toxic to marine life.

Oil Containment

Construction sites can also create hydrocarbons due to dredging operations. In this case, turbidity barriers should be lined with oil sorbent booms parallel to the barrier. This can be anchored directly to the turbidity barrier and will absorb the hydrocarbons before they can reach the barrier.

Construction Use: The ideal solution for any type of construction project, including:

⊘ Dredging

⊘ Bridge construction

⊘ Dam removal and restoration

⊘ Marina/harbor projects (bulkheads, piers, retaining walls)

⊘ Port and terminal projects (groins, dikes, breakwaters)

⊘ Ferry landings

⊘ Pipeline crossings

⊘ Coastal and shoreline restoration and rehabilitation

⊘ Intake construction

Turbidity Barrier

Turbidity Barrier is an economical , universal barrier for intercepting oil spills and other floats on waters. It is made of high strength vinly fabric with light weight foam inside. The Floating turbidity barrier is widely used on rivers, harbors , lakes, offshore oil platforms and other waters, due to its fast install and easy operation.

Turbidity barriers are used to keep the top edge of the barrier above water level. Standard depth of 5 feet with custom depths available. Staked barriers can be used in shallow water.

5’X50’ Turbidity Barrier

Type1 Specification

Floating Turbidity Barrier Basic structure diagram

1. End connector 2. Floatation 3. Ballast 4. Shirt 5. Flexibility gap section 6. Stiffener ( according to design) 7. Tension member 8. Anchor Point 9. Fin H1 : Freeboard (height above water) H2: Draft ( height below water) H : Width ( H1 + H2) L : Length WL : Water level

18.5oz laminated vinly/pvc fabric meets the following specification

| Construction | 1300 Denier | 9x9/sq.inch |

| Weight | 18.5oz/sq.yd | ASTM D-2374 |

| Adhesion | 15 lb/inch | ASTM D-751-95 |

| Grab Tensile | 390 x 370lbs | ASTM D- 5034 |

| Tear Strenght | 96x86 lbs | ASTM D- 2261 |

• Heat sealed seams

• 5/8” polypropylene twisted rope edge reinforcement

• 6”x6”x48” EPS foam blocks

• #4 brass grommets in edge for laced connection

• Smart “Z” connector as option

• ¼” galvanized steel ballast chain

Features

• Economical Silt Control

• Easy to Connect and Install

• Effective Control in Shallow or Slow Moving Areas

• Strong Impermeable PVC Barrier

• Brightly Colored for Easy Spotting

• Lengths Up to 100' to Fit Various Size Projects

• 4 in. Flotations to Fit Smaller Areas

Applications

Construction Sites - Silt and dirt sediments from construction move through the air and eventually land in the surrounding water areas. Turbidity barrier sit in the water and stop silt, dirt, or debris from continuing past the barrier, eventually causing the sediment to settle to the bottom.

Environmental Remediation - Turbidity barriers can also be used in environmental remediation to prevent toxic chemicals and heavy metals from leaving the worksite.

Marine Life Protection - Turbidity barriers work to control the release of organics in the water column, which at concentrated levels can be toxic to marine life.

Oil Containment

Construction sites can also create hydrocarbons due to dredging operations. In this case, turbidity barriers should be lined with oil sorbent booms parallel to the barrier. This can be anchored directly to the turbidity barrier and will absorb the hydrocarbons before they can reach the barrier.

Construction Use: The ideal solution for any type of construction project, including:

⊘ Dredging

⊘ Bridge construction

⊘ Dam removal and restoration

⊘ Marina/harbor projects (bulkheads, piers, retaining walls)

⊘ Port and terminal projects (groins, dikes, breakwaters)

⊘ Ferry landings

⊘ Pipeline crossings

⊘ Coastal and shoreline restoration and rehabilitation

⊘ Intake construction

Head Office

NCIF Group

127 Fuzhou Road N.

Qingdao 266034, China

+ 86 532 8569 7596

US. Office

NCIF USA Corp

17800 Castleton St STE 665

City of Industry, CA 91748

+ 1 229 237 2570